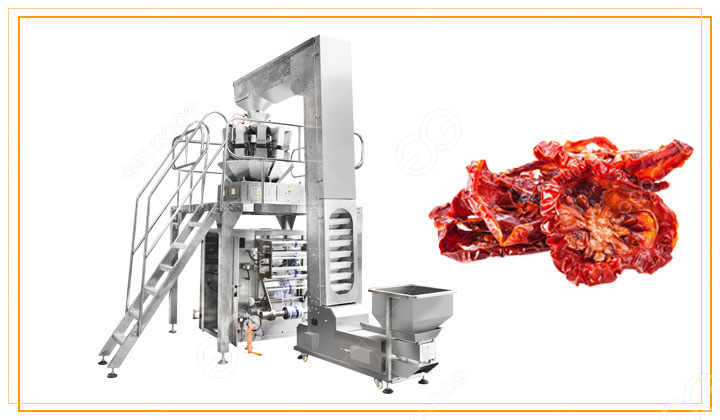

The dried tomato chips packaging machine can automatically complete all the packaging processes of dried tomato measuring, feeding, filling, bag making, sealing, hanging hole, date printing, inflation (nitrogen/air) exhaust, and dried tomato conveying, and automatically complete the counting. The use of a shaker-type cup adjustment device can adjust the packaging capacity of dried tomatoes at any time during the operation of the machine, reducing material loss and improving work efficiency.

翻译结The dried tomato packaging machine can automatically complete all the packaging processes of dried tomato measuring, feeding, filling, bag making, sealing, hanging hole, date printing, inflation (nitrogen/air) exhaust, and dried tomato conveying, and automatically complete the counting. The use of a shaker-type cup adjustment device can adjust the packaging capacity of dried tomatoes at any time during the operation of the machine, reducing material loss and improving work efficiency

Dried Tomato Chips Packing Machine Parameter

Model | GG-LK720 | GG-LK520 |

Film width | max 720mm | max 520mm |

Bag width | 110-350mm | 90-250mm |

Bag length | 100-420mm | 80-350mm |

Packing speed | 10-50bags/min | 10-70bags/min |

Packing range | 150-4000ml | 150-2000ml |

Film thickness | 0.04-0.10mm | 0.04-0.10mm |

Power | 4kw/220v 50-60Hz | 3kw/220v 50-60Hz |

Machine size | 1780*1350*2000mm | 1430*1200*1700mm |

Machine weight | 800kg | 650kg |

Air consumption | 0.8m³/min 0.8mpa | 0.4m³/min 0.6mpa |

Dried Tomato Chips Packing Machine Advantages

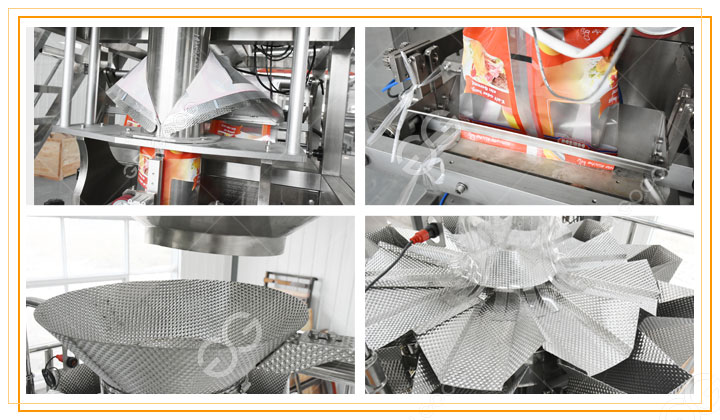

1. PLC automatic control, man-machine interface, simple operation and maintenance

2. Equipped with servo film pulling, photoelectric tracking system, accurate precision

3. Integrated weighing and packaging, saving space and cost to the greatest extent

4. The air circuit control and the circuit control are separated independently, the noise is small, and the circuit is more stable

5. The deviation adjustment of the packaging bag only needs to be adjusted on the touch screen, and the operation is simple

6. The whole machine adopts a closed mechanism to effectively prevent dust from entering the inside of the machine

Dried Tomato Chips Packing Machine Features

1. Multilingual interface, easy to understand;

2. Ten storable programs, easy to replace;

3. Servo film pulling system with accurate positioning;

4. Various packaging styles and beautiful cuts;

5. Stable and reliable PLC program system;

6. Unloading, bag making, sealing, coding synchronization;

7. The vertical and horizontal sealing temperature is controllable, suitable for all kinds of films;