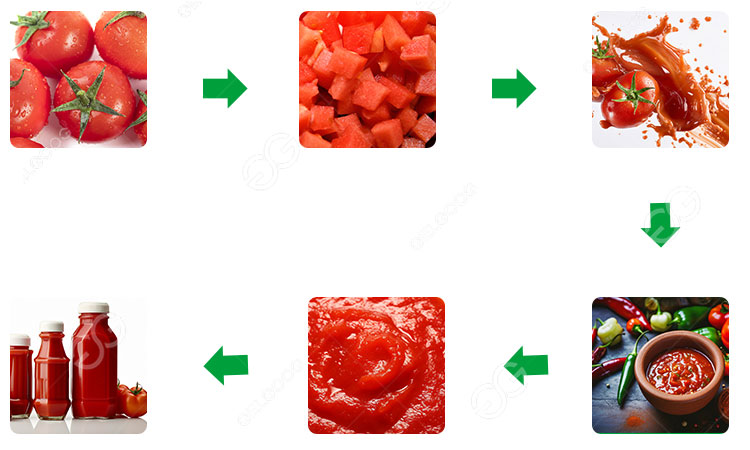

Tomato Sauce Processing Flow Chart

The production process of tomato sauce involves multiple steps, each of which directly affects the quality of the final product. Below is a tomato sauce processing flow chart, along with a description of each step.

Washing: Fresh tomatoes are washed to remove surface dirt, impurities, and pesticide residues, ensuring the raw materials are clean.

Crushing: The washed tomatoes are fed into a crusher and broken into small pieces for easier subsequent processing.

Preheating to deactivate enzymes: The crushed tomatoes are heated quickly to deactivate enzymes, prevent browning and nutrient loss, and preserve the natural color and flavor of the tomatoes.

Pulping: The preheated tomatoes are passed through a pulping machine to remove the skin, seeds and coarse fibers, resulting in a smooth tomato pulp.

Seasoning: According to the product recipe, add seasonings such as salt, sugar, and vinegar to the tomato paste to adjust the taste and flavor.

Vacuum Concentration: The prepared tomato puree is concentrated under vacuum conditions, evaporating excess water and achieving the desired consistency. The vacuum environment helps lower the boiling point, reducing the damage to flavor and nutrients caused by high temperatures.

Sterilization: The concentrated tomato sauce undergoes high-temperature instantaneous sterilization to eliminate microorganisms, extend shelf life, and preserve quality as much as possible.

Finished product: The sterilized tomato sauce is the finished product. The factory can then fill and package it into different specifications according to sales needs.

The entire tomato sauce processing flow emphasizes hygiene and efficiency, aiming to produce a safe, delicious, and long-shelf-life tomato sauce.