-

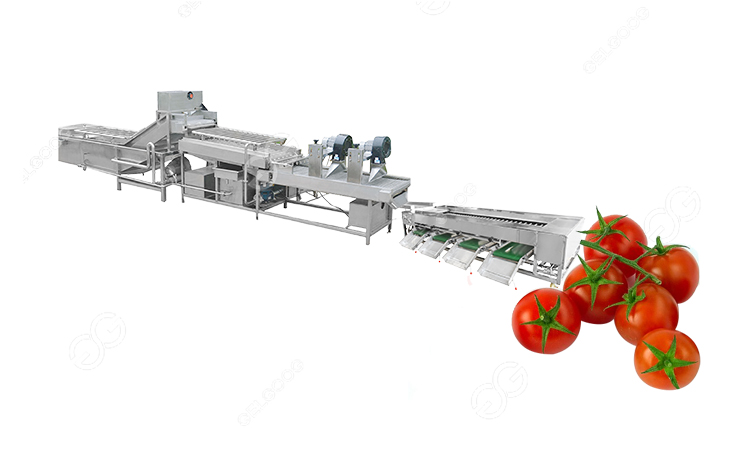

Tomato Washing and Sorting Machine Price

Date : Feb 27,2024 Comment : No CommentsThe tomato washing and sorting machine price is about $8,000 to $12,000 USD, depend on the capacity, features, brand, etc.

See More > -

Tomato Sorting Machine How It Works?

Date : Feb 18,2024 Comment : No CommentsTomato sorting machine how it works? The purpose of sorting is achieved by changing the gap between the rollers.

See More > -

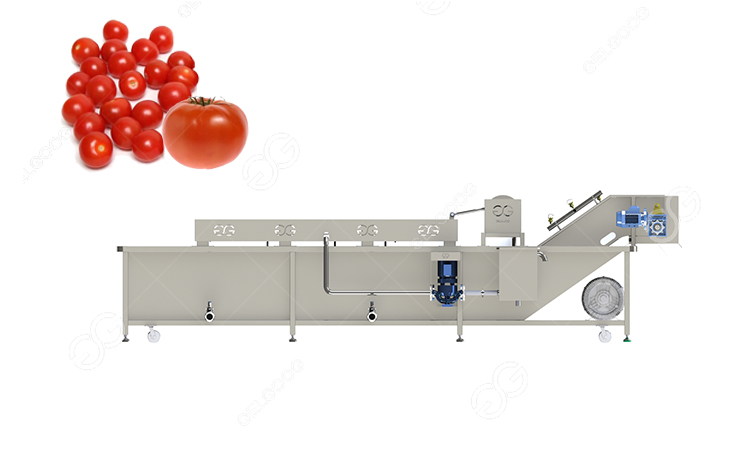

Spain Customer Bought Automatic Tomato Washing Machine

Date : Feb 07,2024 Comment : No CommentsThe Spain customer bought the tomato washing machine to improve tomato processing process.

See More > -

What Is A Tomato Size Grading Machine?

Date : Feb 02,2024 Comment : No CommentsWhat Is a tomato size grading machine? It divides tomatoes into different grades based on their size.

See More > -

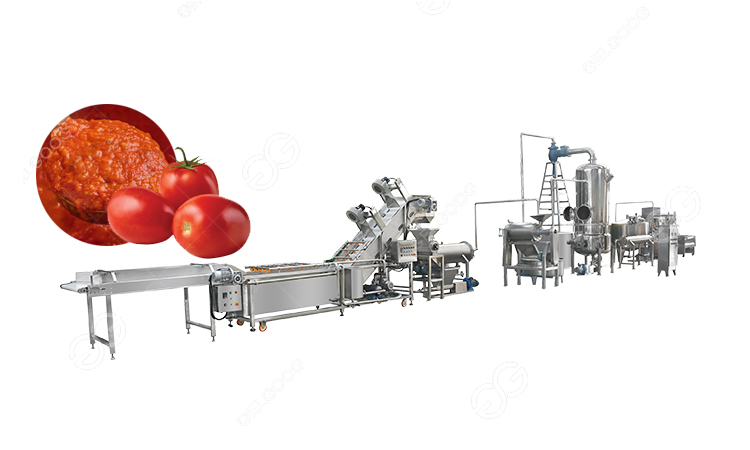

What Are The Methods of Processing Tomato Paste?

Date : Jan 26,2024 Comment : No CommentsWhat are the methods of processing tomato paste? Washing and cleaning, peeling and deseeding, pulping, concentration, heat treatment, packaging, etc.

See More > -

What Is The Price of Tomato Grading Machine?

Date : Jan 18,2024 Comment : No CommentsWhat is the price of tomato grading machine? The price range from approximately $8,000 to $20,000 USD

See More > -

How Does A Tomato Sorting Machine Work?

Date : Jan 12,2024 Comment : No Commentshow does a tomato sorting machine work? For size and weight sorting machine, the working principle is different, let see together.

See More > -

How to Wash Cherry Tomatoes?

Date : Jan 04,2024 Comment : No CommentsHow to wash cherry tomatoes? Pre-sorting and inspection, high-pressure water jets, vortex washing, etc.

See More > -

Tomato Ketchup Process Flow Chart

Date : Dec 28,2023 Comment : No CommentsThe tomato ketchup process flow as washing and inspection, peeling and deseeding, cooking and reduction, seasoning and flavor enhancement, pasteurization, etc.

See More > -

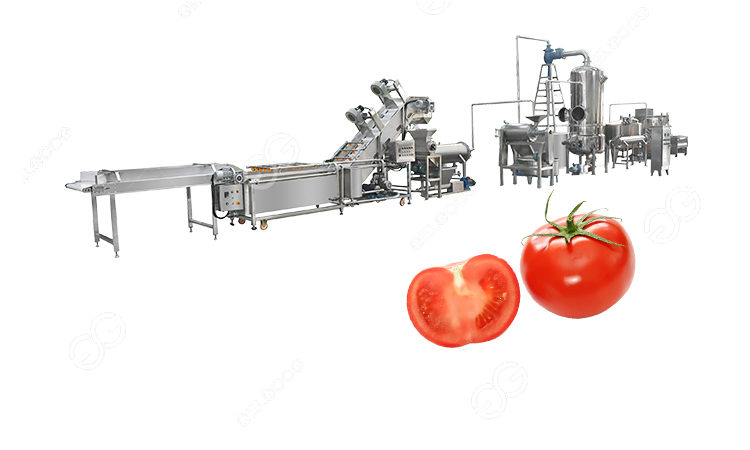

How Is Tomato Paste Manufactured?

Date : Dec 22,2023 Comment : No CommentsHow is tomato paste manufactured? Selecting the right tomatoes, sorting and washing, peeling and seed removal, juicing and pulp extraction, evaporation and concentration, pasteurization, packaging, etc.

See More > -

What Machine Is Used to Process Tomato Paste?

Date : Dec 14,2023 Comment : No CommentsWhat machine is used to process tomato paste? Washing machine, crushing machine, pulping machine, concentration machine, sterilization machine, etc.

See More > -

Tomato Processing Steps in Factory

Date : Dec 07,2023 Comment : No CommentsThe tomato processing steps in factory include washing and sorting, peeling and deseeding, blanching and preheating, pulping and juice extraction, etc.

See More > -

Tomato Sauce Manufacturing Line in California

Date : Nov 30,2023 Comment : No CommentsA customer from California has recently bought a tomato sauce manufacturing line from our company, to built the new factory.

See More > -

How Do You Pasteurize Tomato Sauce?

Date : Nov 23,2023 Comment : No CommentsHow do you pasteurize tomato sauce? By professional pasteurizer machines:Preparation-filling-heating-holding-cooling

See More > -

What Is The Use of Tomato Grader?

Date : Nov 16,2023 Comment : No CommentsWhat is the use of tomato grader? Grading tomatoes by their size, precise and efficient, no damage caused

See More >