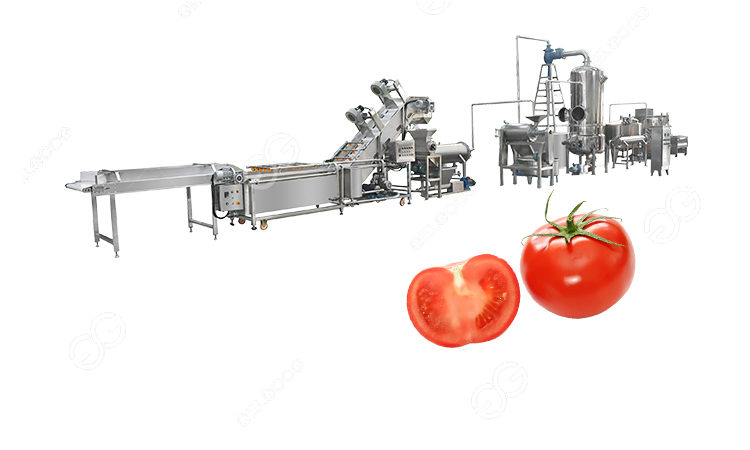

Tomato Processing Steps in Factory

Tomatoes are a versatile and widely used ingredient in various culinary delights, and their journey from the vine to the table involves a series of meticulous processing steps in a factory. Depending on the desired finished product, be it canned tomatoes, tomato sauce, ketchup, or diced tomatoes, the processing steps will vary. In this article, we will explore the typical tomato processing steps in a factory, highlighting the variations based on the end product.

Harvesting and transportation:

The first step in tomato processing is the careful harvesting of ripe tomatoes from the fields. To maintain freshness and quality, it is crucial to transport the harvested tomatoes to the processing facility promptly. Transportation methods vary, but they often involve trucks equipped with proper ventilation to prevent spoilage.

Reception and inspection:

Upon arrival at the processing facility, the tomatoes undergo a thorough inspection. Damaged or overripe tomatoes are removed to ensure the final product's quality. This step is critical in maintaining the standards set for the specific end product.

Washing and sorting:

The tomatoes are washed to remove dirt and debris, and then sorted based on size and color. This ensures uniformity in the processing and contributes to the consistency of the final product.

Peeling and deseeding:

Depending on the intended product, tomatoes may undergo peeling and deseeding processes. For certain products like canned tomatoes or tomato sauce, removing the skin and seeds helps achieve a smoother texture. This can be done using steam or hot water baths to facilitate the peeling process.

Blanching and preheating:

Blanching involves exposing the tomatoes to hot water or steam for a short period, followed by rapid cooling. This step is essential for products like diced tomatoes, as it helps in easy removal of the skin and preserves the color and flavor. Preheating is also done to prepare the tomatoes for subsequent processing steps.

Pulping and juice extraction:

After blanching, the tomatoes are pulped to break them down into a homogenous mixture. Juice extraction follows, separating the liquid from the pulp. This step is crucial for products like tomato juice or puree.

Concentration:

To create products with thicker consistency, such as tomato paste, the extracted juice undergoes concentration through heating and evaporation. This process removes excess water, resulting in a more concentrated tomato product.

Seasoning and cooking:

For products like ketchup or seasoned tomato sauces, additional ingredients such as sugar, salt, and spices are added. The mixture is then cooked to blend the flavors and achieve the desired consistency.

Filling and packaging:

The final step involves filling the processed tomato product into appropriate containers, whether cans, bottles, or pouches. The packaging is designed to preserve the product's freshness and protect it from external contaminants.

Heat treatment and sterilization:

Depending on the product and packaging type, heat treatment and sterilization may be applied to ensure the elimination of bacteria and other microorganisms, extending the shelf life of the tomato products.

Tomato processing in a factory is a complex and highly regulated process that varies depending on the intended end product. Whether it's canned tomatoes, tomato sauce, ketchup, or other derivatives, each step plays a crucial role in delivering a high-quality product to consumers.