How to Wash Cherry Tomatoes?

Cherry tomatoes are a popular and versatile ingredient in various culinary applications, making them a staple in many food processing factories. To ensure the highest quality and safety standards, it is crucial to implement effective washing procedures during the manufacturing process. This article explores how to wash cherry tomatoes.

Pre-sorting and inspection:

Before the washing process begins, it is essential to pre-sort and inspect cherry tomatoes. Remove any damaged or spoiled tomatoes, foreign materials, or debris to ensure that only high-quality produce enters the washing line. This initial step helps maintain hygiene and prevents contamination during subsequent stages.

High-pressure water jets:

One of the primary methods for washing cherry tomatoes in a factory is the use of high-pressure water jets. These jets are strategically positioned to target the tomatoes from various angles, effectively removing dirt, pesticides, and other residues. The force of the water should be carefully calibrated to achieve optimal cleaning without causing damage to the delicate skin of the cherry tomatoes.

Vortex washing:

Vortex washing involves creating a swirling water movement that agitates the tomatoes gently. This technique helps dislodge any remaining impurities and ensures thorough cleaning. Implementing a controlled vortex washing system allows for consistent results while preserving the integrity of the cherry tomatoes.

Chlorine or sanitizing solution rinse:

To eliminate bacteria and pathogens, factories often incorporate a chlorine or other sanitizing solution rinse as part of the washing process. This step is crucial for enhancing food safety and extending the shelf life of cherry tomatoes. Care should be taken to use the appropriate concentration of sanitizing solution to achieve effective disinfection without compromising product quality.

Air drying:

After the washing process is complete, it is important to allow the cherry tomatoes to air dry. Air drying helps remove excess water and further reduces the risk of microbial growth. Implementing a controlled drying system ensures that the tomatoes are not subjected to excessive heat or prolonged exposure, preserving their freshness.

Quality control measures:

Integrating quality control measures throughout the washing process is vital for identifying and addressing any issues promptly. Regular inspections, automated monitoring systems, and employee training contribute to maintaining consistency and ensuring that the highest standards of cleanliness are met.

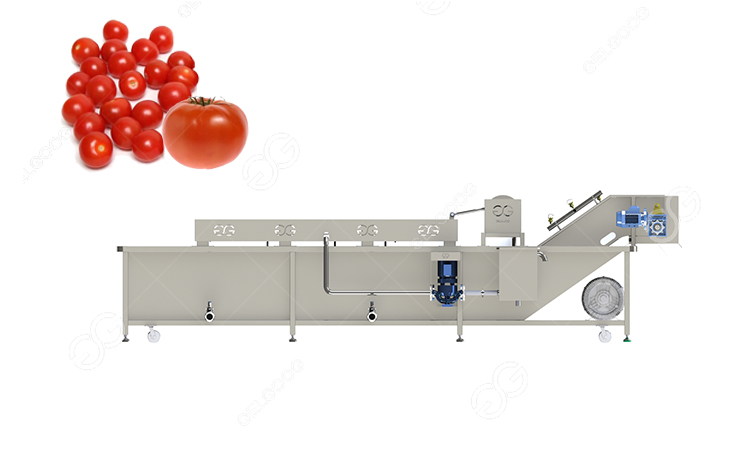

Washing cherry tomatoes in a factory setting requires a meticulous approach to guarantee product safety and quality. By implementing pre-sorting, high-pressure water jets, vortex washing, sanitizing solutions, air drying, and rigorous quality control measures, manufacturers can optimize the washing process and deliver premium cherry tomatoes to consumers. The tomato washing process always completed by professional tomato washing machine, if you are interested, contact us now.