Tomato Paste Production Line Price

Tomato paste is a versatile ingredient used in a wide range of products, from sauces to soups. To meet the growing demand for this essential ingredient, companies invest in tomato paste production lines. However, determining the price of a tomato paste production line is a complex process that depends on various factors.

Factors affecting tomato paste production line prices

1. Production capacity:

The primary factor influencing the price of a tomato paste production line is its production capacity. Larger capacity lines, capable of processing more tomatoes per hour, are generally more expensive than smaller ones. Production capacity is often measured in tons of tomatoes processed per hour.

2. Automation level:

The degree of automation in a production line significantly affects the price. Highly automated lines reduce labor costs and increase efficiency but come at a higher initial investment. Automation can involve automated sorting, washing, peeling, and packaging processes.

3. Materials and build quality:

The choice of materials and build quality of the production line components can vary widely. Stainless steel components, which are corrosion-resistant and durable, are more expensive than alternatives. A robust build quality ensures the production line's longevity.

4. Energy efficiency:

Energy-efficient production lines are not only cost-effective in the long run but also reduce the environmental impact. Energy-efficient components and designs may add to the upfront cost but lead to savings over time.

5. Processing technology:

The technology used for tomato paste production can vary. Some lines employ traditional hot-break methods, while others use more modern cold-break processes. The choice of technology affects the price and the quality of the final product.

6. Customization:

Customization to fit specific needs or regional requirements can increase the price. Customized lines are designed to handle specific types of tomatoes or unique processing conditions.

7. Support and services:

The inclusion of support services like maintenance, training, and technical assistance in the purchase package can influence the overall cost. These services can be essential for the smooth operation of the production line.

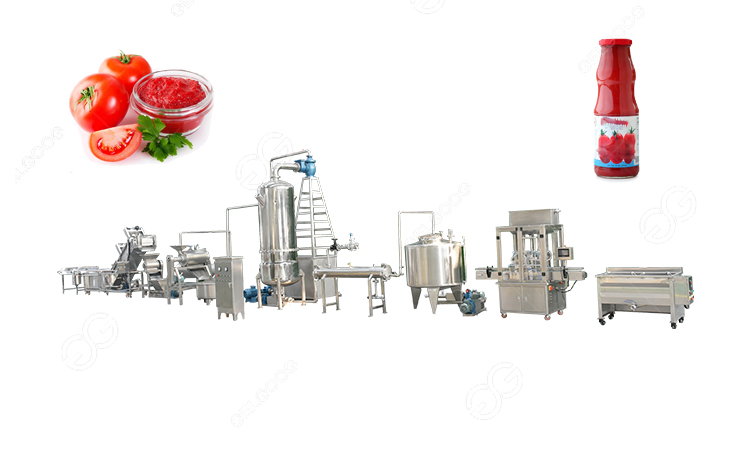

8. Composition of tomato paste production lines

A typical tomato paste production line consists of several key components:

Reception and sorting: Tomatoes are unloaded, sorted, and inspected for quality.

Washing and cleaning: The tomatoes go through a washing process to remove dirt and debris.

Peeling and deseeding: Depending on the recipe, the tomatoes may need to be peeled and deseeded.

Pulping and refining: Tomatoes are crushed into a pulp and refined to the desired consistency.

Evaporation: Excess water is evaporated to concentrate the tomato pulp.

Sterilization and packaging: The concentrated tomato paste is sterilized and then packaged into various containers.

The price of a tomato paste production line is closely related to its composition and various other factors. Companies must carefully assess their needs and budget to choose the right production line that balances efficiency, quality, and cost-effectiveness. Additionally, considering the long-term benefits, including energy efficiency and support services, is crucial when making this investment. Ultimately, the goal is to produce high-quality tomato paste efficiently, meeting consumer demands while ensuring a competitive advantage in the market.