How Are Fresh Tomatoes Processes?

Fresh tomatoes, vibrant and succulent, are a staple ingredient in countless dishes around the world. Yet, the journey from the vine to the store shelf involves a series of meticulous processes to ensure quality, freshness, and safety. But how are fresh tomatoes processed?

Harvesting:

The journey begins in the fields, where skilled farmers carefully harvest ripe tomatoes from the vines. Timing is crucial, as tomatoes are picked at the peak of ripeness to ensure maximum flavor and nutritional content. Modern farms often employ mechanized harvesters equipped with gentle picking mechanisms to minimize damage to the delicate fruit.

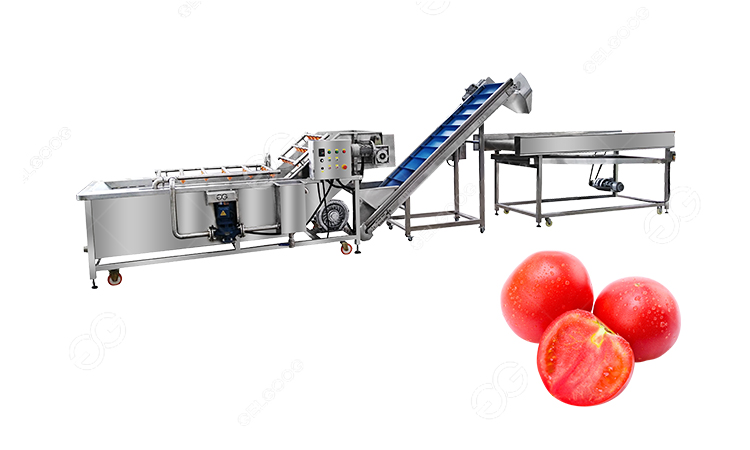

Cleaning:

Once harvested, the tomatoes undergo thorough cleaning to remove any dirt, debris, or residue from the field. This is typically done using a combination of water and brushes to gently scrub the surface of the tomatoes. Some facilities may also use food-grade disinfectants to ensure sanitation and food safety standards are met.

Air-drying:

After cleaning, the tomatoes are air-dried to remove excess moisture. This step is crucial to prevent the growth of mold and bacteria during storage and transportation. Air-drying also helps enhance the tomatoes' shelf life by reducing the risk of spoilage.

Grading:

Next, the tomatoes are carefully sorted and graded based on various criteria such as size, color, and ripeness. This ensures uniformity in appearance and quality, allowing consumers to select tomatoes that meet their preferences. Automated grading machines equipped with advanced sensors and imaging technology are often used to achieve precise and consistent results.

Packaging:

Once graded, the tomatoes are ready for packaging. They may be packed in various formats, including bulk containers for wholesale distribution or consumer-ready packaging for retail sale. Common packaging options include clamshells, plastic bags, or punnets, each designed to protect the tomatoes while maintaining freshness and visual appeal.

Quality control:

Throughout the processing journey, stringent quality control measures are in place to uphold the highest standards of quality and safety. Skilled inspectors carefully monitor each step of the process, conducting visual inspections, quality assessments, and compliance checks to ensure that only the finest tomatoes make it to market.

Transportation and storage:

Finally, the packaged tomatoes are transported to distribution centers and ultimately to retail stores where they are made available to consumers. During transportation, temperature-controlled vehicles are often used to preserve freshness and prevent spoilage. At distribution centers and stores, tomatoes are stored in cool, well-ventilated areas to maintain optimal conditions until they are purchased by consumers.

In conclusion, the journey of fresh tomatoes from the vine to the store shelf is a carefully orchestrated process that involves tomato harvesting, cleaning, air-drying, grading, packaging, and stringent quality control measures. Each step is essential to ensure that consumers receive tomatoes of the highest quality, flavor, and nutritional value.